Skip

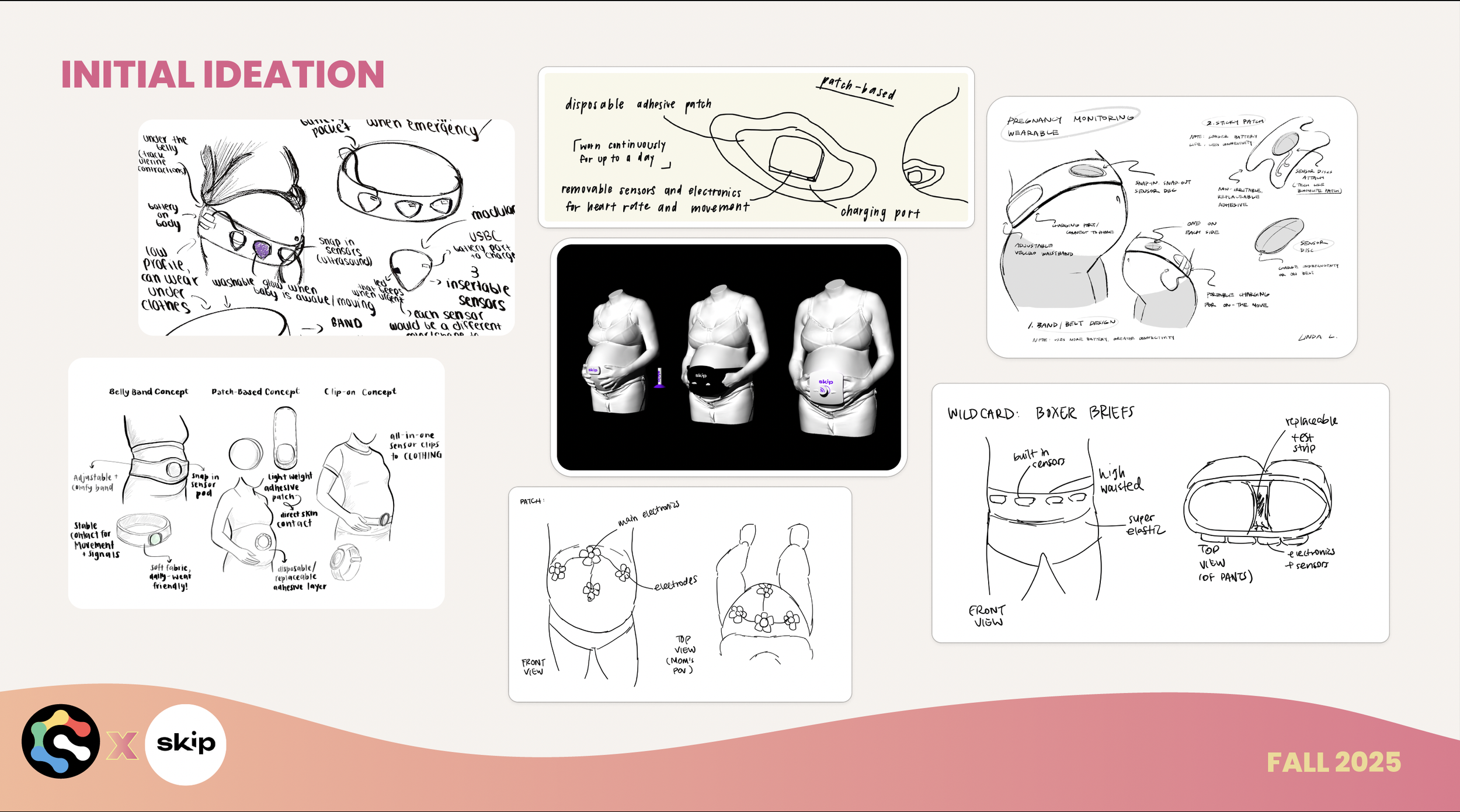

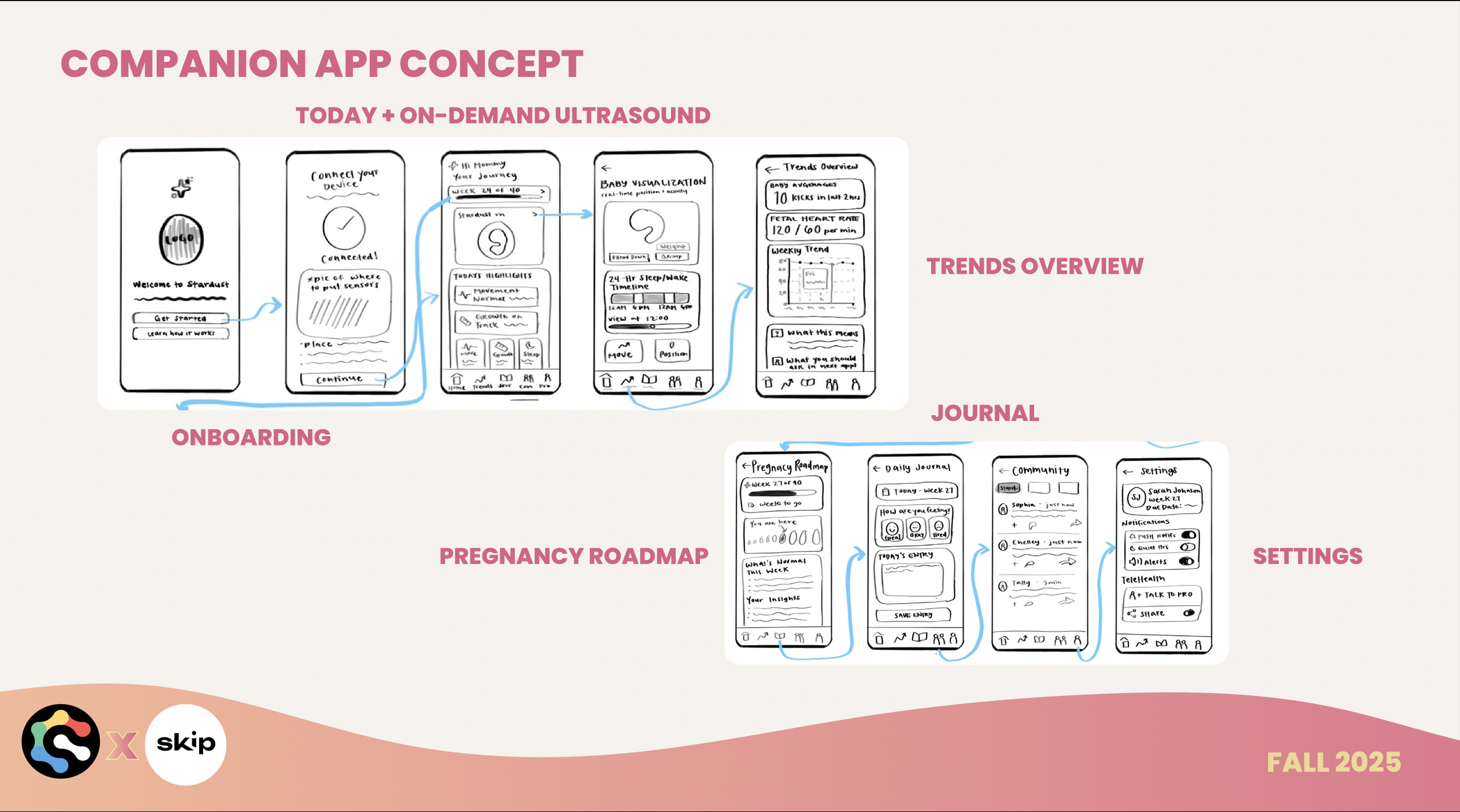

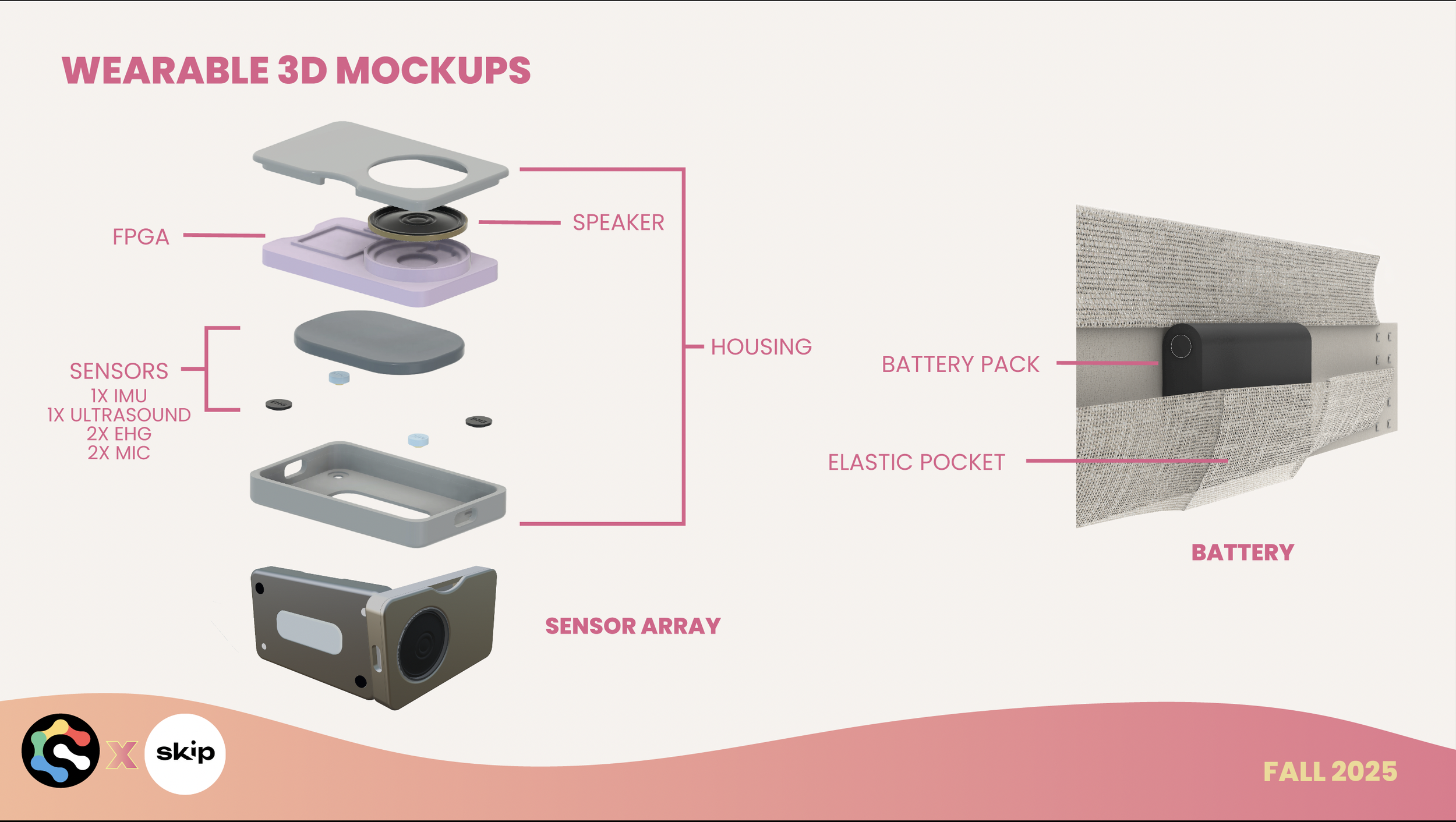

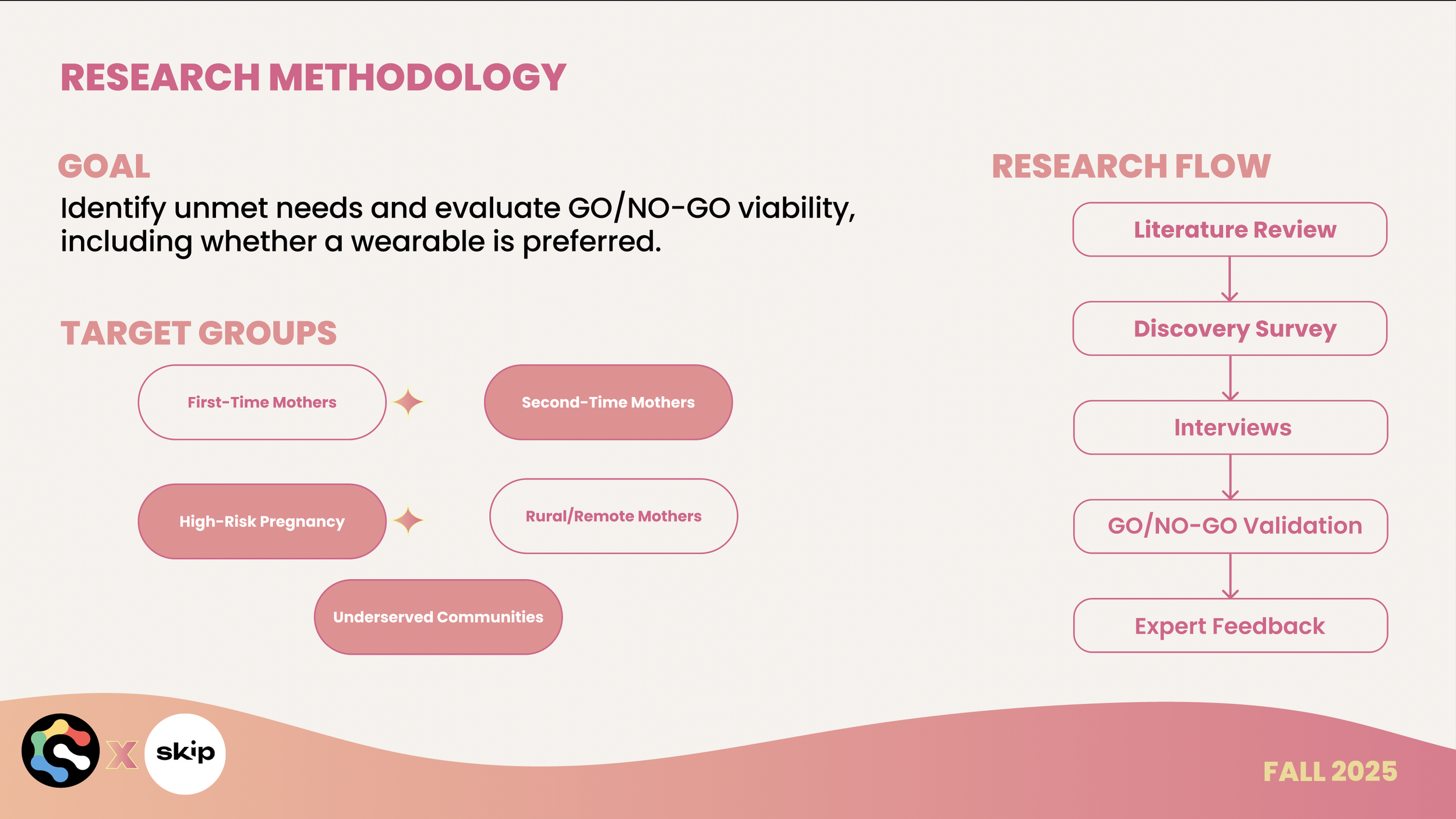

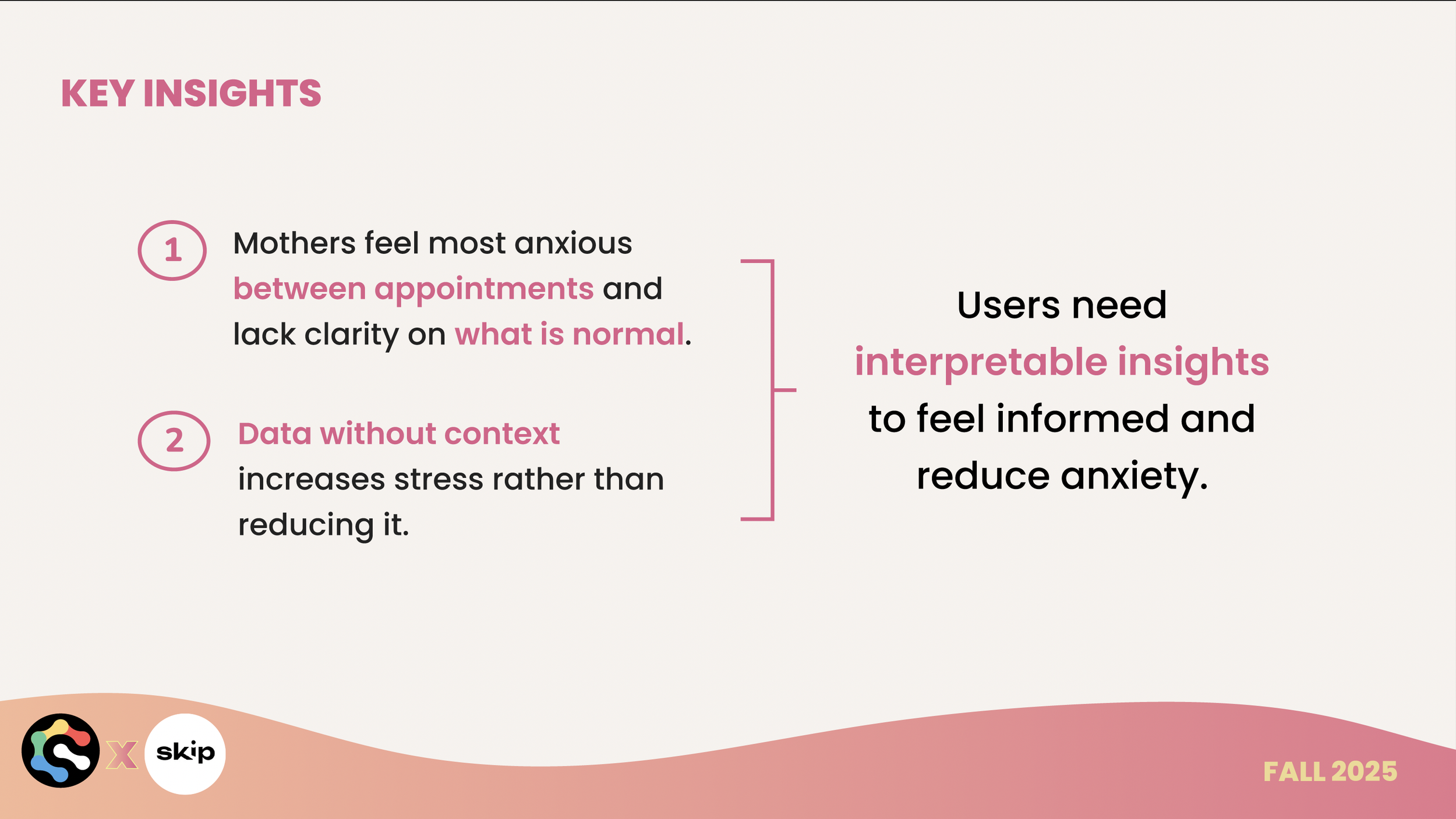

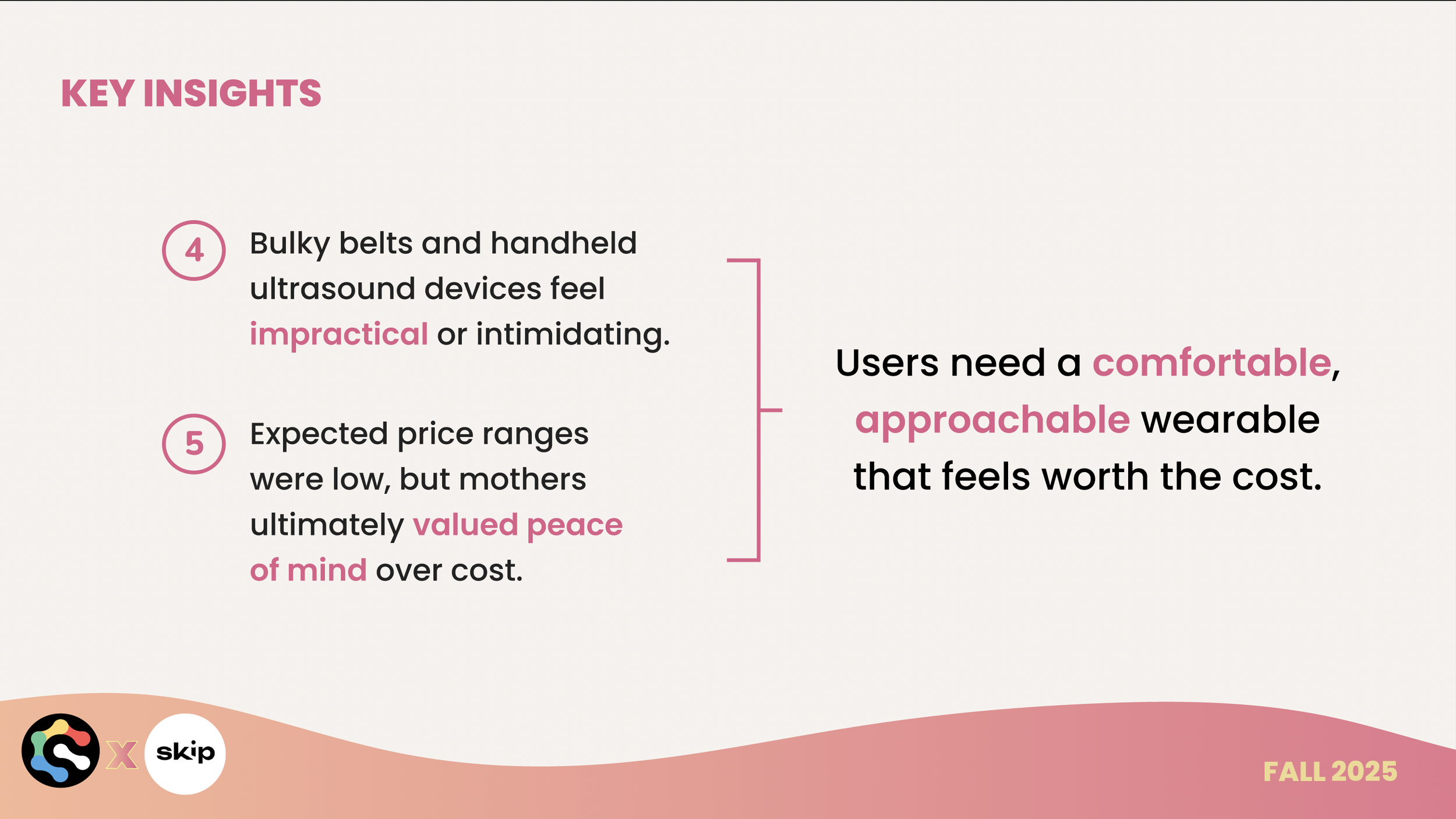

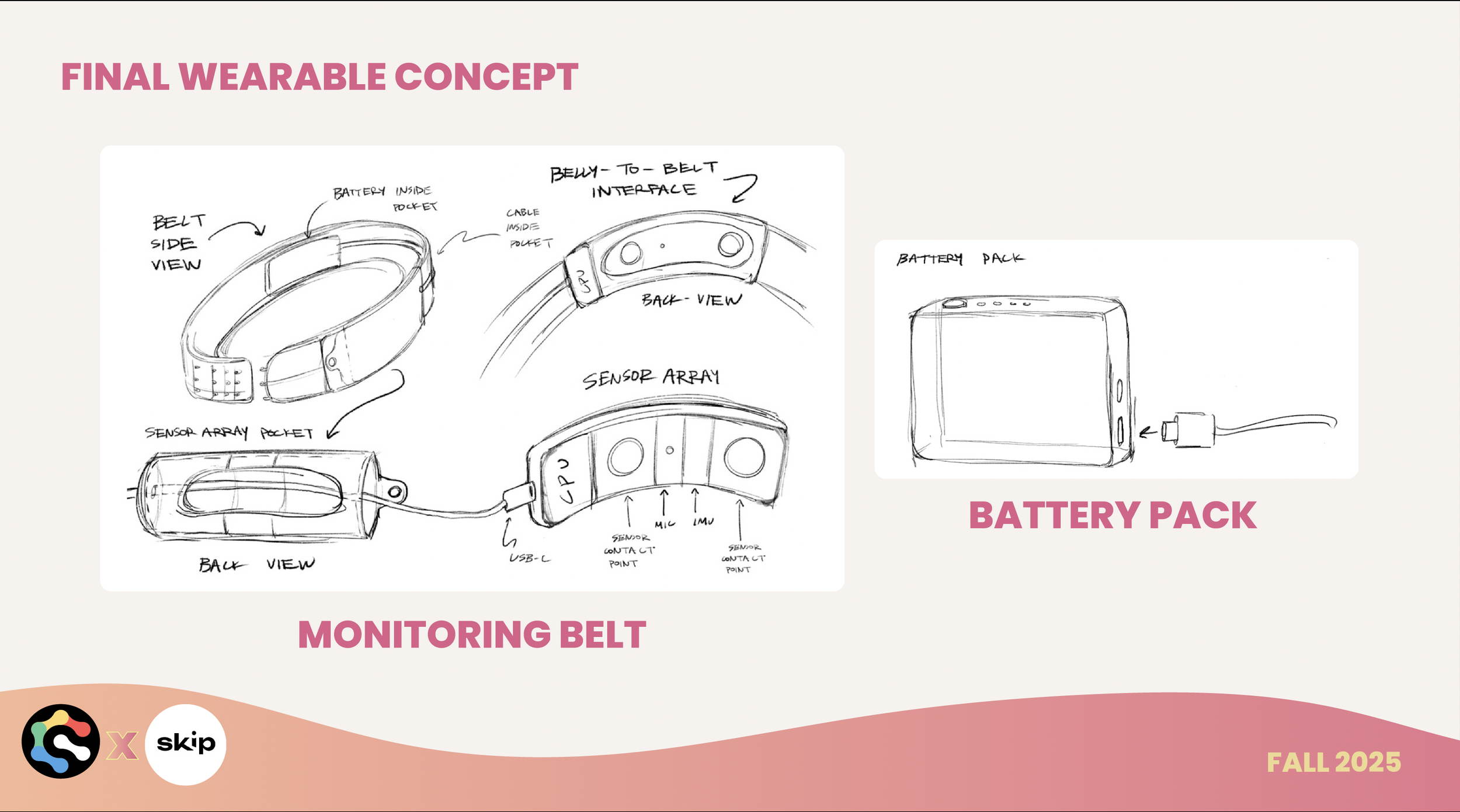

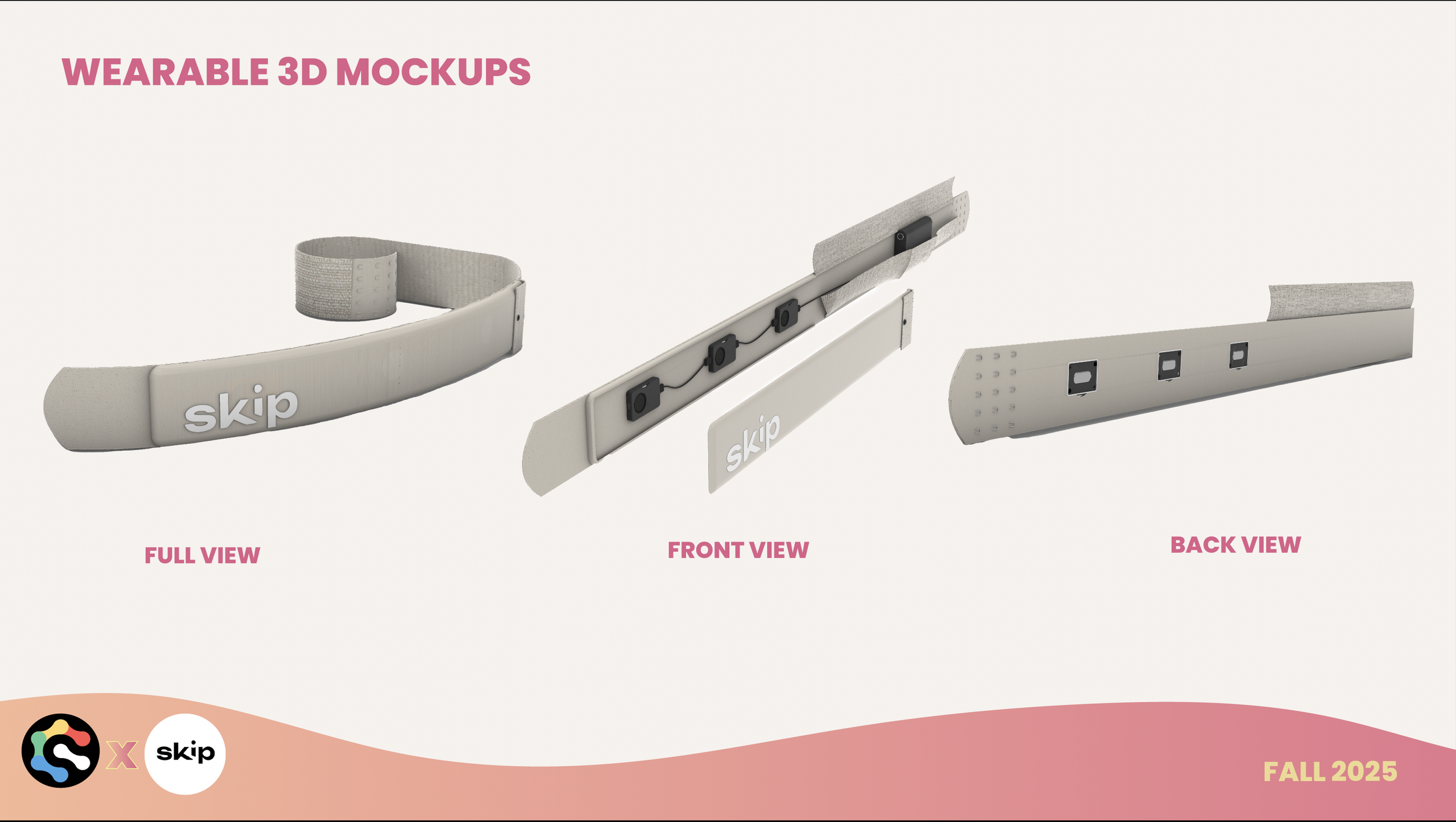

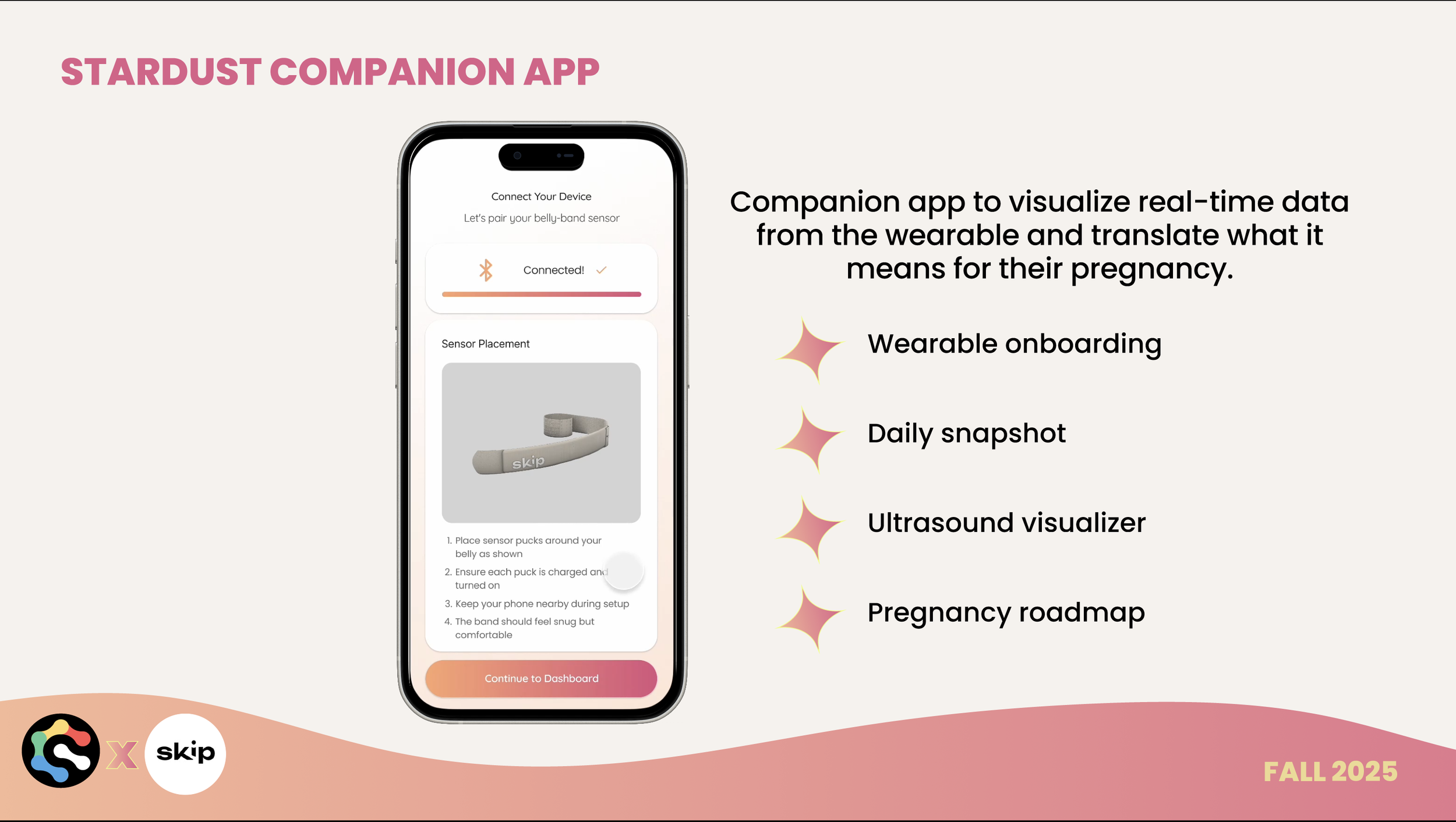

As an Product Design Engineering Consultant at Skip, I worked through the human-centered design process, where I utilized user interviews to create a physical and digital mockup of a wearable + companion app to aid in the diagnostics for expectant mothers. During this project we used a range of 3D modeling software, from Rhino, to Blender, to Onshape to create renderings. In the physical mockup, 3D printed housings and sensor arrays were sewed and integrated with elastic to understand the form and function.

To create the physical mockup of this product, a 3D printed housing and dimensioned sensor arrays were used to get a sense of form factor.

For improved user experience and wearable conformability, sensor pods and battery were sewn in to a band to maximize visualization potential. A lot of experimentation dealt with soft goods: i.e., elastic materials, band materials, material thickness, etc…

Next steps: experimenting with battery capacity and connection mechanisms between each sensor pod. Additionally, finding ways to integrate the sensor pod within the band for improved user experience.