Hexabrace

HexaBrace is a rehabilitative device that monitors posture and provides real-time cues to help users maintain proper form during high-intensity exercises.

ME292C: Design of Morphing Matter and Mechanisms

Problem Space + Goal

Incorrect spinal posture during heavy lifting is a major contributor to musculoskeletal injuries. The risk of muscle strain, ligament damage, and/or intervertebral disc problems increase when using improper lifting techniques and can result in the necessity for rehabilitation or, in severe cases, chronic pain.

The device aspires to reduce the prevalence of LBP while, in parallel, accelerating safe movement skill acquisition by delivering continuous, personalized feedback during weightlifting. It will also serve as a foundation for utilizing soft robotic/morphing matter technology for active injury prevention in athletics and rehabilitation in clinical recovery.

User Persona

The target audience for this product is people in physical therapy and athletes. This problem space is focused on anyone who is lifting with a high impact on the back and lower back. For the user persona, we have Michael Reed, an NFL athlete who has only ever trained with personal trainers. He wants to be able to perform heavy lifting on his own time to increase his gains, train independently and confidently, obtain feedback based form correction, and train in a safe environment.

Need + Feature Identification

In order to understand what sort of features to include, based on the problem space, these were the brainstormed needs. This weighted matrix helps with placing importance and priority on certain needs over others. Based on the determined needs and prioritization of certain solutions, this is the brainstormed list of features.

Intitial Design

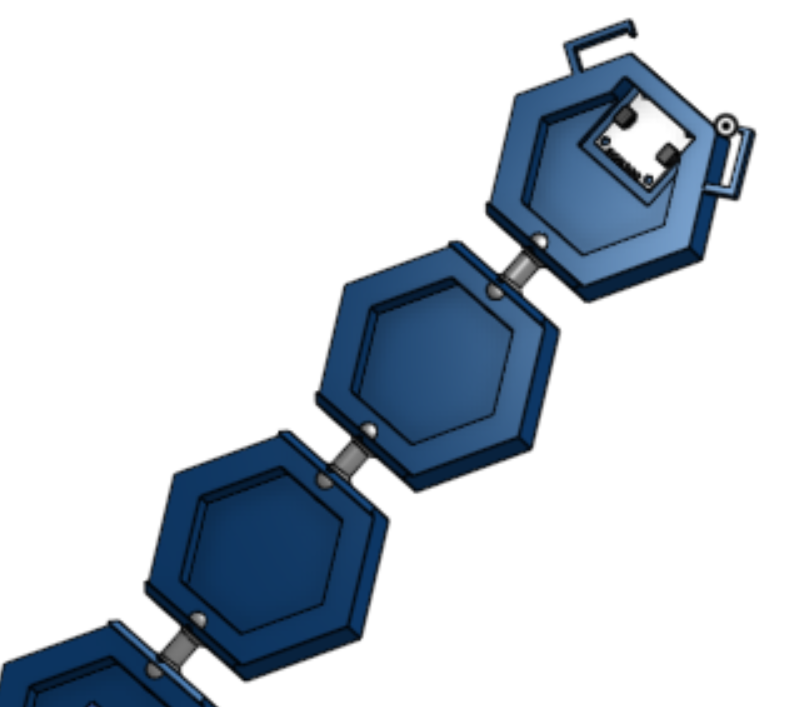

Utilizing a modular arrangement allows for increased customizability for different body types and ensures proper spinal alignment to get the most accurate angle monitoring.

Utilizing a hinged mechanism to ensure flexibility between hex cells.

Intitially, we were going to utilize a a rigid cell like structure that is connected to a vest for easy wearability. The device will consist of a modular array of hexagonal cells positioned along the spine. Each cell is embedded with an inertial measurement unit (IMU) and can be connected to other cells via the pneumatic actuators and clipping mechanisms. The actuators will be anchored between hexagonal cells and are made of three layers: an extensible (flexible) layer, a non-extensible layer, and an internal air bladder.

The prototype functionality will depend on air supply from a system of solenoids connected to a 16g CO2 cartridge. The system of solenoids and IMUs will be connected using a microcontroller. When the device detects poor posture, the entrance solenoid will be signaled to pressurize the actuator. When pressurized, the bladder inflates asymmetrically, causing expansion towards the non-extensible side. This will generate directional force and enable the actuator to produce corrective cues. While the force generated by the actuators will not be sufficient to overcome the musculoskeletal force generated by the user, it will alert the wearer and assist in adjusting posture in real time.

Iteration

As we tested pumping air into elastic actuators (nylon-TPU), this led to a lot of air leakage, so we decided to iterate and utilize a different signaling mechanism for feasibility purposes. Testing of elastic actuation was through a nylon-TPU air bladder. We soldered together two sheets and used a hose clamp to connect the air bladder to the pump.

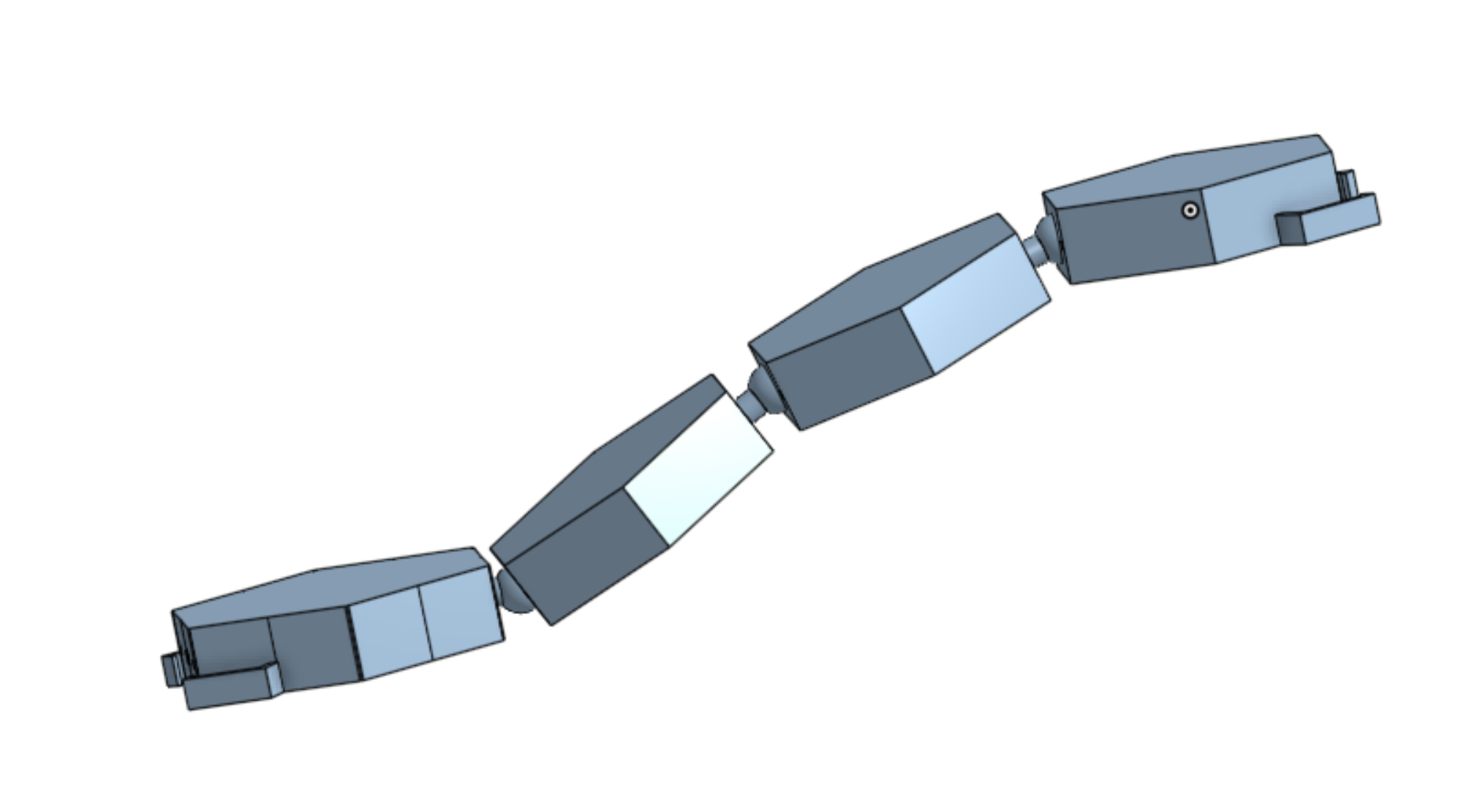

The bioinspired concepts of deformative movement were used for signaling posture correction. Attaching a servo motor to a string, whenever the IMU detects a change in pitch or roll that is abnormal to a user’s “normal” or equilibrium, the motor will pull on the string leading to deformative movement of the brace. We also attached a speaker to the brace to serve as haptic feedback.

Initial designs of hinged mechanisms were maintained, but soon changed to a ball joint mechanism due to restricted movement along the y-axis.

Finalized Concept

1) Based on user position, IMU calibrates.

2) When user arches or slouches their back, the IMU detects the pitch and roll angle, and using proportional control feedback, motor encoder value or how much the motor rotates is based off of that angle.

3) As the motor rotates, it creates tension on the brace through the string that is attached to each cell. (As the string increases in tension, the 3D printed parts act as a form of deformation and start to curve, like an elephant trunk).

4) As the brace deforms, it creates a strain differential (brace starts to pull on the vest), which indicates to the user that they must return to their initially calibrated pitch angle.

5) Once user is back in good posture, they will no longer feel the tension created due to the brace.

Future work and Key Insights

Key Insights

Designing for manufacturability:

I optimized the brace so that the entire mechanism, including the hinge and ball joint, could be printed in a single build. This required experimenting with tolerances to ensure all moving parts printed cleanly and that support interfaces could snap off through simple bending or rotation. Through iteration, I found that a spacing range of 0.1 mm to 0.3 mm produced the most reliable motion without sacrificing structural strength.Packaging and integration:

I explored how the brace could be packaged as part of a wearable system, including attaching it to a vest or fabric layer. This work focused on ensuring the brace could be comfortably secured, properly aligned on the body, and easy for users to put on and take off.

Future Work

Experimenting with different vests/fabrics for better integration

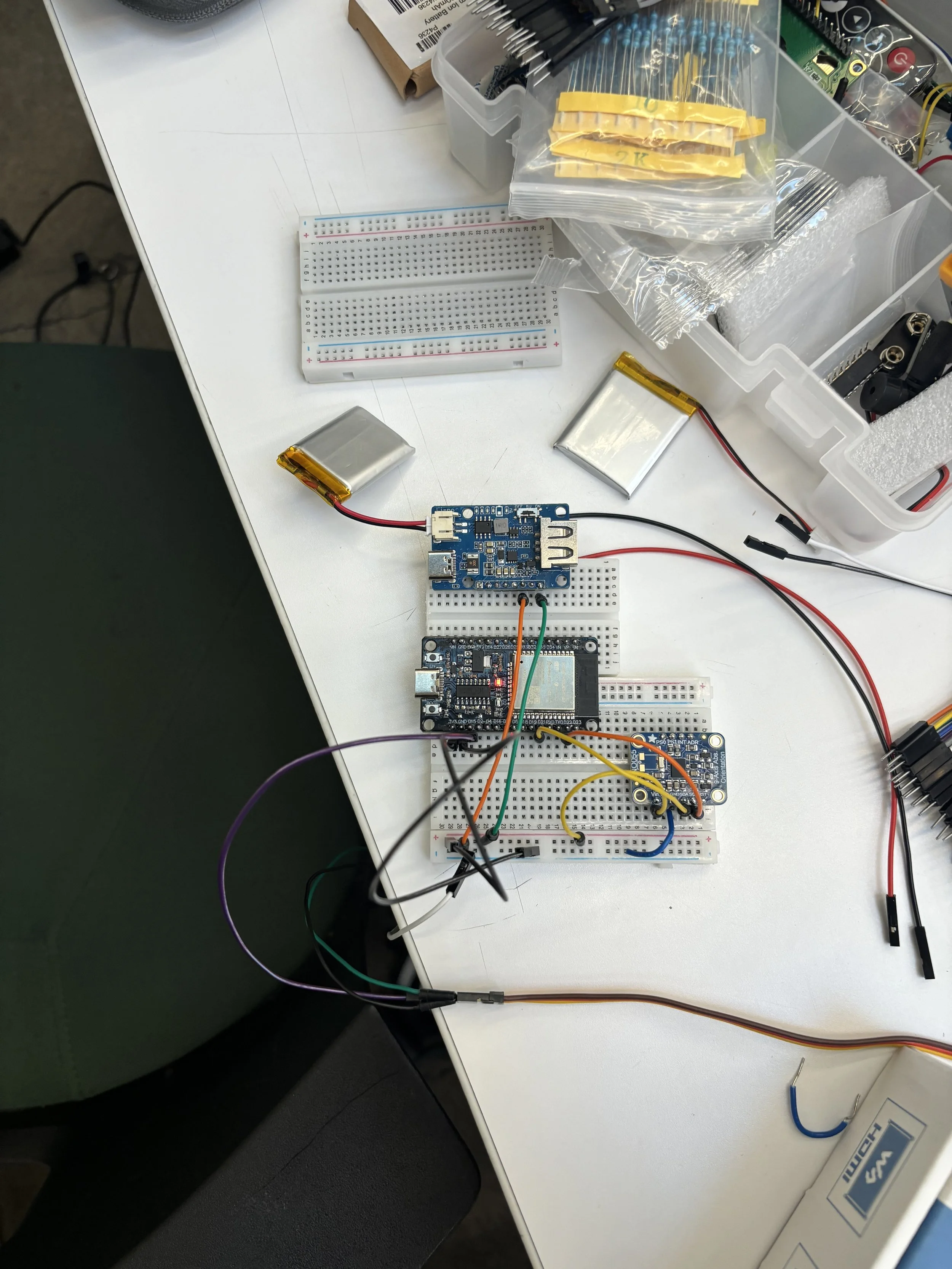

Electronics packaging- want to eventually design PCB (instead of breadboard) for cleaner packaging + easier portability.